Benjamin Dutreux: “It’s the dream project!”

Three days before the start of the Transat Jacques Vabre, in which he took 9th place with Arnaud Boissières, Benjamin Dutreux presented his new Imoca project on October 23rd in Le Havre, supported by his title partner 4CAD, which involves a new boat, an Antoine Koch design built at Multiplast. The Vendée native tells us more.

Benjamin Dutreux, between Yann Penfornis and Stéphane Letheule, president of 4CAD (© DR)

Why did you choose to launch the construction of an Imoca?

Coming back from the last Vendée Globe (10th place), I told my partners that to continue to have the motivation and to put a lot of energy, I needed a project that could stimulate me. And that project was to be able to compete with the best teams and aim to win the Vendée Globe. For more than eight years now, my team and I have been evolving in this Imoca universe, it was time to take this step. And I am lucky that my partners, and 4CAD in particular, agreed to follow me. For me, sportingly, it’s a dream project. I am, however, well aware of the huge amount of work involved in building an Imoca, which is something new for our team. We knew it, but now that we’re getting started, we realize even more that it’s a very complex boat, but that makes it all the more exciting.

How did you choose the architect (Antoine Koch) and the Multiplast yard?

When 4CAD and I formalized the decision to launch construction, we moved heaven and earth to find solutions by consulting architects and yards. We were, moreover, about to propose three options to our partners, when a fourth one arrived last summer, which turned out to be by far the best, at least in terms of feasibility and practicality. Sam (Goodchild) had started working well with his partner (Leyton) on a sistership of Paprec (Yoann Richomme’s future Imoca) when he was contacted by Macif to succeed Charlie (Dalin) with a view to the next Vendée Globe. The fact that he accepted freed up this opportunity to build this sistership at Multiplast, and we were quick to seize it. Antoine Koch proved his ability to design high-performance boats during the last Imoca cycle. And now that he has the perspective of this previous campaign, I am convinced that he has the means to do better than the others; in any case, that is his ambition, which we share. We also agreed on this idea of wanting to win the Vendée Globe. As for Multiplast, for the record, six years ago, there was already talk of us building a boat; I went to see Yann (Penfornis, General Manager), and we met for the first time. The project finally failed, but when we thought about this one, I naturally consulted him again. And finally, with this choice to build in the molds of Paprec, for reasons of timing, environmental impact, and budget balance, we are finally going to work together. It just goes to show that things work out well; we’re returning to the yard we first knocked on the door of a few years ago!

How will the collaboration with the Paprec team go?

There was an immediate good fit between our two teams, which is a huge positive. Yoann (Richomme) and I have known each other from afar for three years on the Solitaire du Figaro, and I’m getting to know him a little better; he’s someone who really likes to discuss things. And it’s the same for his team, which is very open and attentive to what solutions we can bring, even though we have less experience than them. We try to be proactive with them in the choices that are made; I lay my cards on the table with the ideas I’ve noted in my notebook for years, and we try to decide together. The first phase of collaboration is set, with the objective of making the boats as close as possible. And at the end of the construction, if we are still friends, which is clearly our common goal, we will inevitably be winners if we continue to share our data and our experience feedback.

Does a larger and more ambitious project mean a more expanded team around you?

Yes, absolutely. We are already ten full-time, which is a middle Imoca team. The objective is to increase to about fifteen and recruit people in roles we didn’t have before, particularly in the design office. Now that we have started delving into design issues, a lot of information is coming in, and quite a few choices need to be managed. I don’t want us to be passive; I want us to be able to make informed decisions, hence the need to surround ourselves with the right people.

ARCHITECTURE. Multiplast successfully completed the assembly of the dome for the Departmental House of Environment and Observation in Valberg (Alpes-Maritimes) at the end of October. The dome is made up of 16 petals manufactured in Vannes under the responsibility of Samuel Napoleoni and transported for the final kilometers by helicopter. This structure, designed by the firm Wilmotte & Associés Architectes, with whom Multiplast had already built the 5 domes of the Orthodox Cathedral in Paris in 2015, will open its doors to the public in early 2026.

WEBSITE. The new version of the Multiplast website was launched in November, in French then in English. More modern and airy, it provides everything you need to know about the company: presentation of the teams and production facilities, the different strategic areas of activity and the processes used, recruitment section, to join our teams, and news section, where you can find this newsletter.

QUALITY. Multiplast was successfully audited for two and a half days from November 18 to 20 as part of the follow-up for ISO 9001/EN 9100 certification. The next appointment for this formality, which is essential to guarantee the level of production quality to clients, is in one year!

OCEAN RACING. Multiplast received visits from two Imoca teams in recent weeks who entrusted the yard with the construction of their future boats: Dr Mori, president of DMG Mori, accompanied by skipper Kojiro Shiraishi and the team manager, Jacques Caraës, was able to see the progress of the new Verdier design, expected in the course of 2026. For his part, Yoann Richomme also wanted to visit the teams who have just started the construction of his next Paprec, designed by Antoine Koch.

LAUREATE. On December 9, the Carboman Group joined the sixth cohort of the ETIncelles program, an initiative launched by the French government and managed by the Ministry of the Economy, to support the development of ETIs (Intermediate-sized Enterprises) and help them drive their growth.

OCEAN RACING. The 17th edition of the Transat Jacques Vabre was once again an opportunity to highlight boats built partly or entirely at Multiplast, notably with the Ultim victory of SVR Lazartigue (central hull), ahead of Sodebo Ultim 3 and Actual Ultim 4 (ex-Maxi Edmond de Rothschild), and the excellent second place in Imoca for 11th Hour Racing, the former Malizia skippered by Francesca Clapcich and Will Harris.

RECORDS. They are off! On Saturday, November 29, at 2:40 PM, the 100% female crew, led by Alexia Barrier, with Dee Caffari by her side, set off around the world as part of The Famous Project CIC, aboard Idec Sport, the legendary VPLP design built at Multiplast twenty years ago. Their objective: to establish a women’s reference time for this round-the-world route and try to get as close as possible to 40 days, 23 hours, and 30 minutes, the time set in January 2017 on the same trimaran by Francis Joyon, who still holds the Jules Verne Trophy. Their trajectory can be followed here.

Nicolas Abiven: “We are still at the very beginning of the story”

This end of 2025 marked an important milestone for the Solidsail project by Chantiers de l’Atlantique, as Neoliner Origin, equipped with two SolidSail rigs and composite sails manufactured by Multiplast, completed its first commercial transatlantic rotations between Saint-Nazaire and the American continent. As for Orient Express Corinthian, a luxury cruise ship from the Accor Group brand featuring three masts, she is undergoing first sea trials in December. This is an opportunity to speak with Nicolas Abiven, the engineer who is leading this wind propulsion project for Chantiers de l’Atlantique.

© Michel Perrin

How did the commissioning of Neoliner Origin go?

Crossing the North Atlantic in autumn for the start-up proved to be a great challenge. For its first transatlantic crossing, the crew faced 60-70 knots of wind, conditions in which you have to learn to use the entire system, which was not easy. But once you’ve done Everest in winter, it’s easier to tackle Mont-Blanc in summer—it’s pretty much the same thing here! And it allows us to learn a lot. We see that many things are working well, especially the sails, and that others still need improvement. We hope to finish this first cycle of improvements in January when the ship returns to Saint-Nazaire.

And what is the status of Orient Express?

It’s going very well. The first ship has been afloat since June, the three masts were installed at the beginning of September, all the dockside testing necessary before going to sea was completed in early December, and it began its first sea trials immediately after. The project benefits from everything we are learning with Neoline, so it is naturally a little easier; there are no blocking points. Commissioning is scheduled for the second quarter of 2026, while the second ship, whose metal structure is under construction, as are the masts being manufactured at Solidsail Mast Factory in Lanester, will be launched a year later.

Speaking of which, how is Solidsail Mast Factory (the factory that produces the masts, commissioned last spring) operating today?

It is gaining momentum. We currently have 22 people on permanent contracts, and we will increase to 35 during 2026; the order book is full with four masts to be built. Three for Orient Express No. 2, the fourth being the G800, a rig that will be capable of holding 800 square meters of total sail area (compared to 1,500 square meters for the masts manufactured so far), which we intend for ships in the 100-150 meter range. Our machining robot has been running since May/June, the familiarization phase is going very well, and we are learning to master the draping robot, with which we draped the first plies for our clients at the end of November, which is a very big step for us.

What is your perspective on this emerging wind propulsion market?

I have been immersed in this sector for almost ten years, so I sometimes find it hard to step back! Let’s say there are two phases. The first with demonstrators and proofs of concept, which are mainly financed in Europe, where there are quite a few R&D aid mechanisms. And a second phase, where the challenge is precisely to address the market’s issues, particularly in terms of price, which is the big challenge of the moment. With SolidSail, we have clearly positioned ourselves in a separate part of the spectrum: our rigs propel ships as soon as there is a little wind, because we offer the largest sail areas—almost twice as much as our competitors—and very light solutions. We are the only ones doing this today. With the G800, we are going to complete our offering with systems close in size to some of our competitors while remaining lightweight. We hope that with this range, we will meet a need and that our rigs will appeal to a portion of the wind propulsion market. We need to convince people; we have good prospects and we hope to announce new orders within a few weeks. Bearing in mind that we are still at the very beginning of the story. The market will gradually sort itself out and the path is still fraught with pitfalls, including competition from the Chinese, who are already very aggressive on prices; we didn’t necessarily expect that.

Multiplast and Cubik, a virtuous partnership

For a year now, Multiplast has been supported by the Cubik group, the French leader in supporting operational excellence initiatives, in order to optimize its production and organization processes. Explanation.

It all began at the end of 2024 when, through Chantiers de l’Atlantique, Multiplast came into contact with the Cubik group, which has been advising and training companies for just over twenty years around the concept of operational excellence—more than 120 consultants spread across four agencies (Nantes, Paris, Toulouse, and Lyon), with a turnover of more than 20 million euros. “By talking with them, I saw the benefit of a collaboration to improve the management and organization of our workshops,” comments Jean-Denis Bargibant, president of the Carboman group.

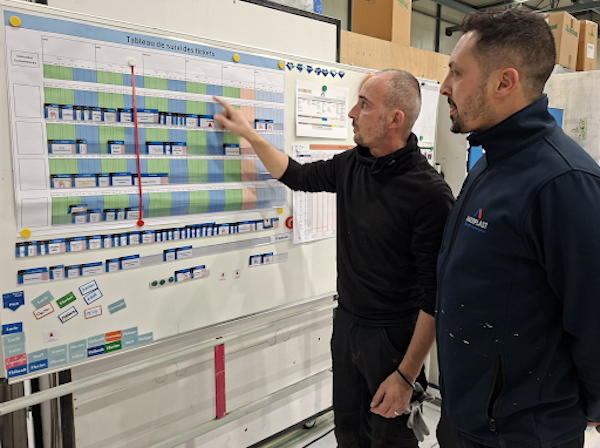

© Multiplast

“Multiplast’s request was part of a context of strong activity, with an unprecedented order book in its history, an increasing diversification, particularly in the defence and aerospace sectors, staff movements that required organizational stability, and the company’s financial performance objectives in the short and long term,” explains Antoine Birot, the consultant in charge of the file for Cubik.

The consultancy’s first mission was to establish a complete diagnosis, which was presented to Multiplast at the end of 2024 and includes, according to the latter, “the strengths of the organization and areas for improvement.” These are broken down into seven points: improving the workshop working environment, refining operational workload management, structuring the supply chain function, developing operational guidance at all levels, growing quality control across the entire value chain, strengthening the design/production relationship, and structuring the overall continuous improvement approach.

From there, a second phase of collaboration was initiated in January 2025 to implement this roadmap, and it will continue until the end of the first quarter of 2026. “What we tell our clients is that our collaboration must be diminishing, in the sense that, over the months and years, we must withdraw so that the process is internalized and clients become autonomous in their performance approach,” explains Antoine Birot. This is gradually becoming the case for Multiplast, who will welcome on board a continuous improvement manager starting January 1st, who will be responsible for continuing the work started with Cubik, either alone or accompanied by the firm.

For Yann Penfornis, CEO of Multiplast, the assessment of the first year is positive: “Cubik’s rational and pragmatic side has allowed us to reorganize certain teams, but also to implement tools for better spatio-temporal organization of our workshops, which is a real challenge for us when the order book is full.” He adds: “Initiating such an approach shows a certain maturity to our clients, and some who recently audited us have actually seen a real difference.”